ABSTRACT

PVDF is a semi-crystalline fluoropolymer and has attracted a lot of interest in a variety of industrial applications because of its special qualities, which include thermal

stability, chemical resistance, and piezoelectricity. A polar phase is present in the β-phase. Sensors, actuators, energy harvesting systems, batteries, filters, chemical

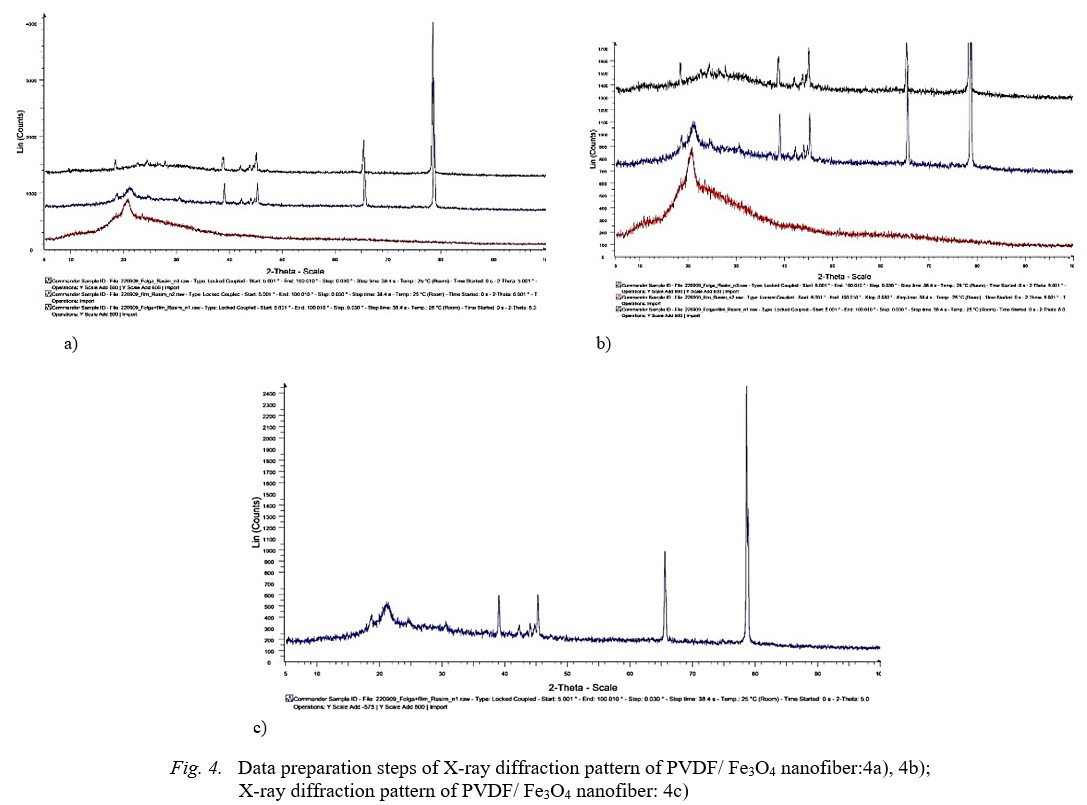

warfare defense, magnetoelectric, and polymer-based composites were among the many applications it was found to have. In this work, the β-phase fraction of the

PVDF/Fe3O4 nanocomposite was measured by X-Ray diffraction analysis.

Keywords: PVDF; Fe3O4; X-ray diffraction; β-phase; nanocoating; high electroactive phase; electrospinning;

DOI:10.70784/azip.1.2025132

Received: 03.03.2025

Internet publishing: 03.04.2025 AJP Fizika E 2025 01 en p.32-36

AUTHORS & AFFILIATIONS

1. Nanotechnology Laboratory. Department of Chemical Engineering, School of Science and Engineering, Khazar University, Baku Azerbaijan

2. Institute of Physics Ministry of Science and Education of Azerbaijan

*e-mail: dilara.sadigova3377@gmail.com

**e-mail: rasim.jabbarov69@gmail.com

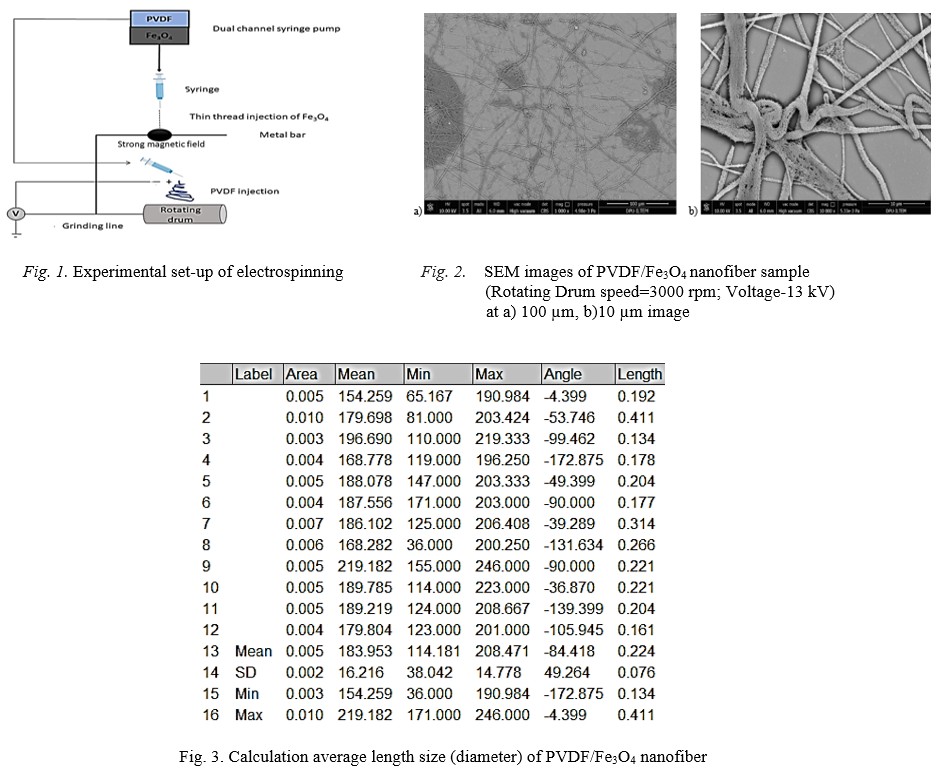

Graphics and Images

Fig.1-2-3 Fig.4

|

[1] S. Lanceros-Me´ndez, P. Martins. First Ed., Magnetoelectric Polymer-Based Composites Fundamentals and Applications Wiley, Germany 2017.

[2] P. Ueberschlag. Sens. Rev. 21, 118, 2001.

[3] S. Bauer, F. Bauer. Springer Ser. Mater. Sci. 157 2008.

[4] Z.W. Ouyang, E.C. Chen, T.M. Wu. Materials 8, 4553, 2015.

[5] A.J. Lovinger. Science 220, 1115, 1983.

[6] V. Sencadas, R.G. Filho, S. Lanceros-Mendez. J. Non-Cryst. Solids 352, 2226, 2006.

[7] G. Botelho, S. Lanceros-Mendez, A.M. Goncalves, V. Sencadas, J.G. Rocha, J. N., G.T. Davis, J.E. McKinney, M.G. Broadhurst, S.C. Roth. J. Appl. Phys. 49, 4998, 1978.

[8] N. Levi, R. Czerw, S. Xing, P. Iyer, D.L. Carroll. Nano Lett. 4, 1267, 2004.

[9] J.Y. Lim, J. Kim, S. Kim, S. Kwak, Y. Lee, Y. Seo. Polymer 62, 11, 2015.

[10] A.S. Motamedi, H. Mirzadeh, F. Hajiesmaeilb, J. Xu, M.J. Dapino, D. Gallego-Perez, D. Hansford. Sens. Actuators A 153, 24, 2009.

[11] P. Martins, A.C. Lopes, S. Lanceros-Mendez. Prog. Polym. Sci. 39, 683, 2014.

[12] S. Harstad, N. D’Souza, N. Soin, A.A. El-Gendy, S. Gupta, V.K. Pecharsky, T. Shah, E. Siores, R.L. Hadimani. AIP Adv. 7, 056411, 2017.

[13] L. Ruan, X. Yao, Y. Chang, L. Zhou, G. Qin, X. Zhang. Polymers 10, 1, 2018.

[14] Y.C. Ahn, S.K. Park, G.T. Kim, Y.J. Hwang, C.G. Lee, H.S. Shin, J.K. Lee. Curr. Appl. Phys. 6, 1030 2006.

[15] C. Ribeiro, V. Sencadas, J.L.G. Ribelles, S. Lanceros-Méndez. Influence of processing conditions on polymorphism and nanofiber morphology of electroactive poly(vinylidene fluoride) electrospun membranes. Soft Mater. 8, 2010, 274–287.

[16] S. Ramakrishna, K. Fujihara, W. Teo, T.-C. Lim, Z. Ma. An Introduction to Electrospinning and Nanofibers; World Scientific Publishing Company: Singapore, 2005

[17] A. Haider, S. Haider, I.-K. Kang. A comprehensive review summarizing the effect of electrospinning parameters and potential applications of nanofibers in biomedical and biotechnology, Arab. J. Chem. 11 (2018) 1165–1188.

[18] Rahul Kumar Singh, Sun Woh Lye, Jianmin Miao. Holistic investigation of the electrospinning parameters for high percentage of β-phase in PVDF nanofibers Polymer 214 (2021) 123366.

[19] S. Gee, B. Johnson, A. Smith. Optimizing electrospinning parameters for piezoelectric PVDF nanofiber membranes, J. Membr. Sci. 563 (2018) 804–812.

[20] J. Zheng, A. He, J. Li, C.C. Han. Polymorphism control of poly (vinylidene fluoride) through electrospinning, Macromol. Rapid Commun. 28 (2007) 2159–2162.

[21] W.A. Yee, M. Kotaki, Y. Liu, X. Lu. Morphology, polymorphism behavior and molecular orientation of electrospun poly (vinylidene fluoride) fibers, Polymer 48 (2007) 512–521.

[22] Zhou, Z.;Wu, X.-F. Electrospinning superhydrophobic-superoleophilic fibrous PVDF membranes for high-efficiency water-oil separation. Mater. Lett. 2015, 160, 423–427.

|